How Does LOPO China Produce Terracotta Panel?

1. Select raw material, choose the best quality clay. After the clay is sifted and coarse broken,stale the clay for six months. During this time, turn the clay over again and again to dry it to appropriate moisture and particles;

2. Transport the raw material to indoor warehouses, and keep the materials staling again to ensure further staling and homogenization of the naturally dried raw materials;

3. Mix the raw material according to the formula, Using professional Raymond machines to crush the raw materials according to certain fineness requirements ;

4. Put the raw material powder into the 3rd stale homogenizing equipment (115 power storage tanks with total reserves of 7,000 tons), and start full automatic computer-controlled dosing;

5. Add water to the prepared dry raw material powder and stir for granulation, and then put it into discharge warehouses with constant temperature and humidity settings;

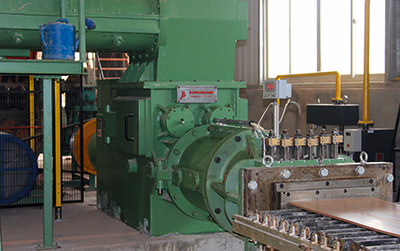

6. Put the granulated raw materials into a vacuum extruder imported from Italy. Now the terracotta facade panel is extrusion forming.

7. Do the inspection of the size and glancing flatness by human, and then send the formed materials into a 80-meter five-layer drying kiln to dry the materials slowly for 8 hours;

8. Send them to a 260-meter-long roller kiln for high temperature burning for 8 hours after drying, do inspection and sifting;

9. After the roller kiln process, do inspection and classification of terracotta panel, and then proceed with product edging and cutting;

10. After inspection and packaging, the final products are stored in the warehouse.

Complete inspection and QA measures

During the whole production process, to make sure the controllability and stability of the product quality, LOPO China sets up rigorous measures for process tracking, inspection and feedback. The company’s professional test room checks and controls the product’s appearance and dimensions constantly(including indicators such as flatness, edge straightness, width dimension, color, etc.), as well as various physical and chemical performance indicators.

Related Reading: Terracotta Panel, LOPO China