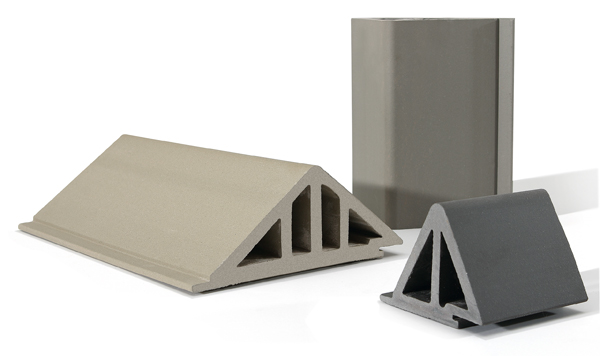

Special Shape Ceramic Louver Baguette

Item No.:CornerMaterial: 100% Natural Clay

Size: 200-2000mm

Usage: Exterior and Interior Wall

CE, ISO9001:2008

Special Shape Ceramic Louver Baguette Specification:

LOPO China Technical Specification:

| TERRACOTTA PANEL Technical Data Sheet | ||||

| NO. | Contents | (300X600X18MM) Terracotta Panel | China N. S. GB/T4100-2006 | EN14411 standard |

| 1 | Water Absorption | 5.4% | (II) 6-10% | (II) 6-10% |

| 2 | Net Weight | 31kg/m2 | no value | no value |

| 3 | Breaking Strength | 3475N | ≥ 900N | ≥ 750N |

| 4 | Frost Resistance | no crack under -60 centigrade | tested value of the report | tested value of the report |

| 5 | Modulus of Rupture | avg. 13.1Mpa, min 11.8Mpa | Avg. ≥ 9Mpa, single value≥ 8Mpa | Avg. ≥ 9Mpa, single value≥ 8Mpa |

| 6 | Earthquake resistance | over 8 degree | no value | No |

| 7 | test under simulated wind load | No breakage under 10Kpa | no value | No |

| 8 | sound insulation | Noise reduction by over 8dB | 7-10dB | No |

| 9 | Wind pressure | 9kPa | tested value of the report | tested value of the report |

| 10 | heat conductivity | 0.32 w/m. k | no value | No |

| 11 | Fire resistance | leval A1 | no value | No |

| 12 | resistance to acid and alkali | Level UA | tested value of the report | No |

| 13 | radioactivity | Class-A decorative material | no value | No |

| 14 | Right angle | 0.1%- -0.2% | within ±1% | No |

| 15 | Size error | 300L: 0.1%- -0.4%600L: 0.2%- -0.5% | with in ±2% , max is within ±2mm, | No |

| 16 | Thickness error | within ±4.5% | within ±10% | No |

| 17 | Diagonal line | -0.5 ~ +0.2 Max 1.0mm | within ±2% | No |

1 – Never Fade

The Wall Panel of Terracotta made up from high quality natural pure argil, via vacuum high pressure extrusion molding, burn out from high temperature. With low consumption and no radiation, light pollution, never fade and can effectively resist ultraviolet radiation, durable, 100% of the repeatable recycling. It’s environmental protection material choice.

2 – Waterproof & Insulation Sound Noise

The Wall Panel of Terracotta cavity design greatly reduces the materials self weight, reduce building façade structure system load, meanwhile, after high temperature firing, can effectively reduce the heat transfer coefficient, make ceramic plate with greater intensity, makes its enhanced against the bad weather, the waterproof is admirable.

3 – Anti Fire &Freeze

Advanced technology and equipment, precise cutting, strict calibrated to ensure the product quality and size stability. The Wall Panel of Terracotta has good security anti fire characteristics, anti acid and alkali corrosion resistant, anti scratch and abrasion. Even face supernormal low or high temperatures, it could keep stable.

4 – Rain Self-cleaning

Clay materials content metal very low, do not produce electrostatic, not easy to absorb dust, dirt not easy deposition, via wind and rain could self cleaning.

5 – Simple Natural

The Wall Panel of Terracotta colors is rich, covers the modern architecture mainstream color design requirements. Natural texture and external clay color collect architectures rich artistic style.

6 – Diversity Styles and Sizes

Leiyuan offers a variety styles and sizes for your chosen, its complete sizes through different product combination and cutting to meet designer’s style requirement.

Lopo was found in 2002, began with specializing in clay brick tiles. Now it owns two industrial parks, one is devoted in clay brick and artificial cultured stone, the other one is focusing on terracotta panel and louver. The total area of industrial parks is more than 540 hectare with total investment more than 3 hundred million.

Lopo is equippeed with the international advanced production line, including the longest roller kiln with automatic temperature control in China, the annual output reached 1.5 million square meters.

80,000 square meter open stockyard with the daily reserve of natural clay raw material amounts to 300,000 tons is the foundation of production and imported molding machines of vacuum extrusion from Italian BONGIOUNNI are the guarantee of qualified products. Domestic longest roller kiln (260 meters) with 428 firing units keeps our terracotta panel’s water absorption under 6%, which reaches European standard.

Related Products

Red Ceramic Rain Screen Louver Manufactured from LOPO China

Item No.:T5018069Material: 100% Natural Clay

Size: LTY(2+5)X18

Usage: Exterior and Interior Wall

CE, ISO9001:2008

Natural Clay Material Building Terracotta Baguette

Item No.:T505064Material: Natural Clay

Size: LTY5X5

Usage: Exterior and Interior Wall

CE, ISO9001:2008

Grey Decorative Facade Wall Baguette

Item No.:T505083Material: Natural Clay

Size: LTY5X5

Usage: Exterior and Interior Wall

CE, ISO9001:2008

Exterior Wall Terracotta Facade Baguette

Item No.:T5010086Material: Natural Clay

Size: LTY5X10

Usage: Exterior and Interior Wall

CE, ISO9001:2008

Square Shape Exterior Wall Terracotta Baguette

Item No.:T505026Material: 100% Natural Clay

Size: 50x(200-2000)x50mm

Usage: Exterior and Interior Wall

CE, ISO9001:2008